Current exploration: Resource Potential

Click the arrows on the map to view

Northwest MSU Extension

MSU EXTENSION

Southwest MSU Extension

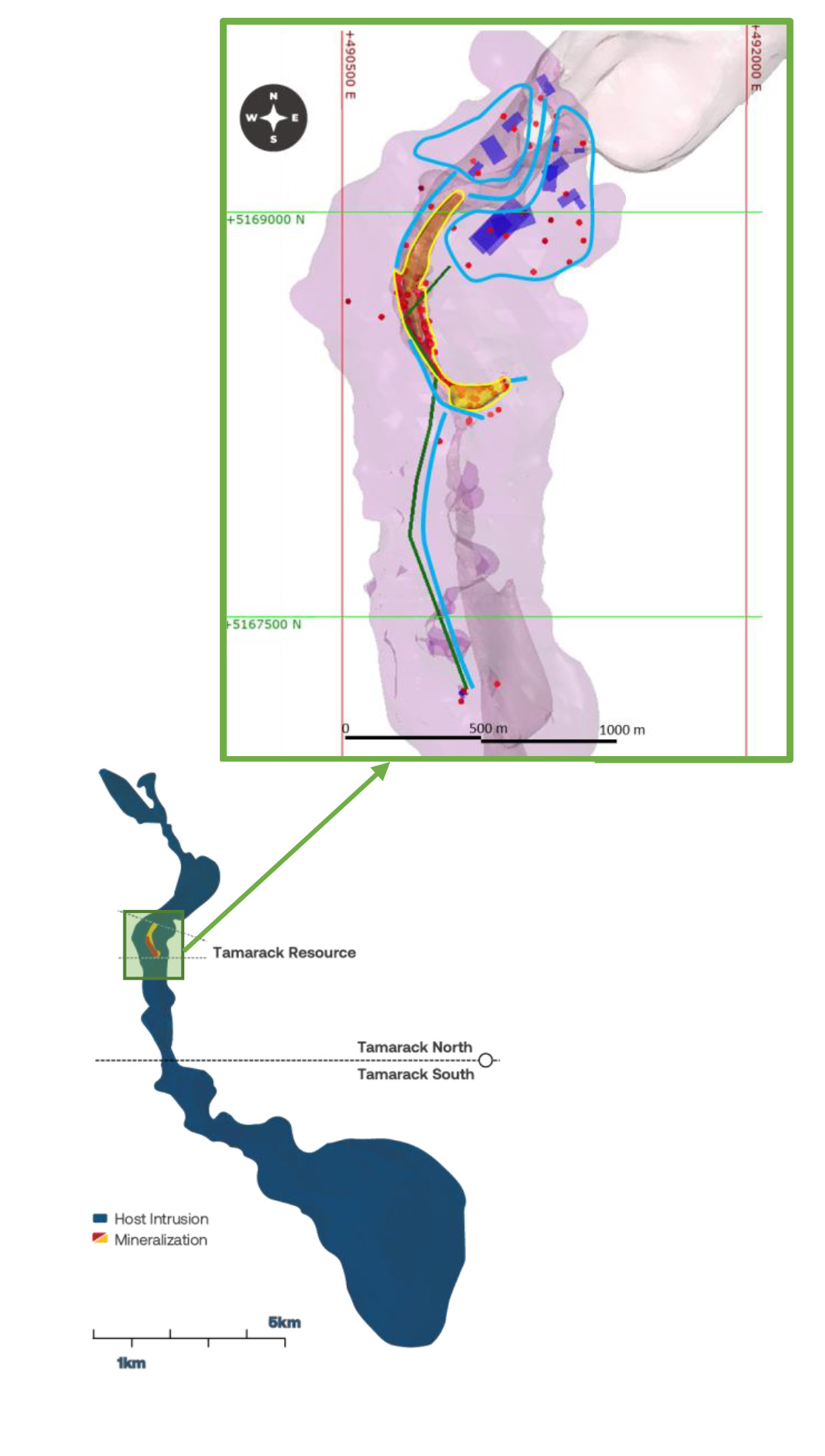

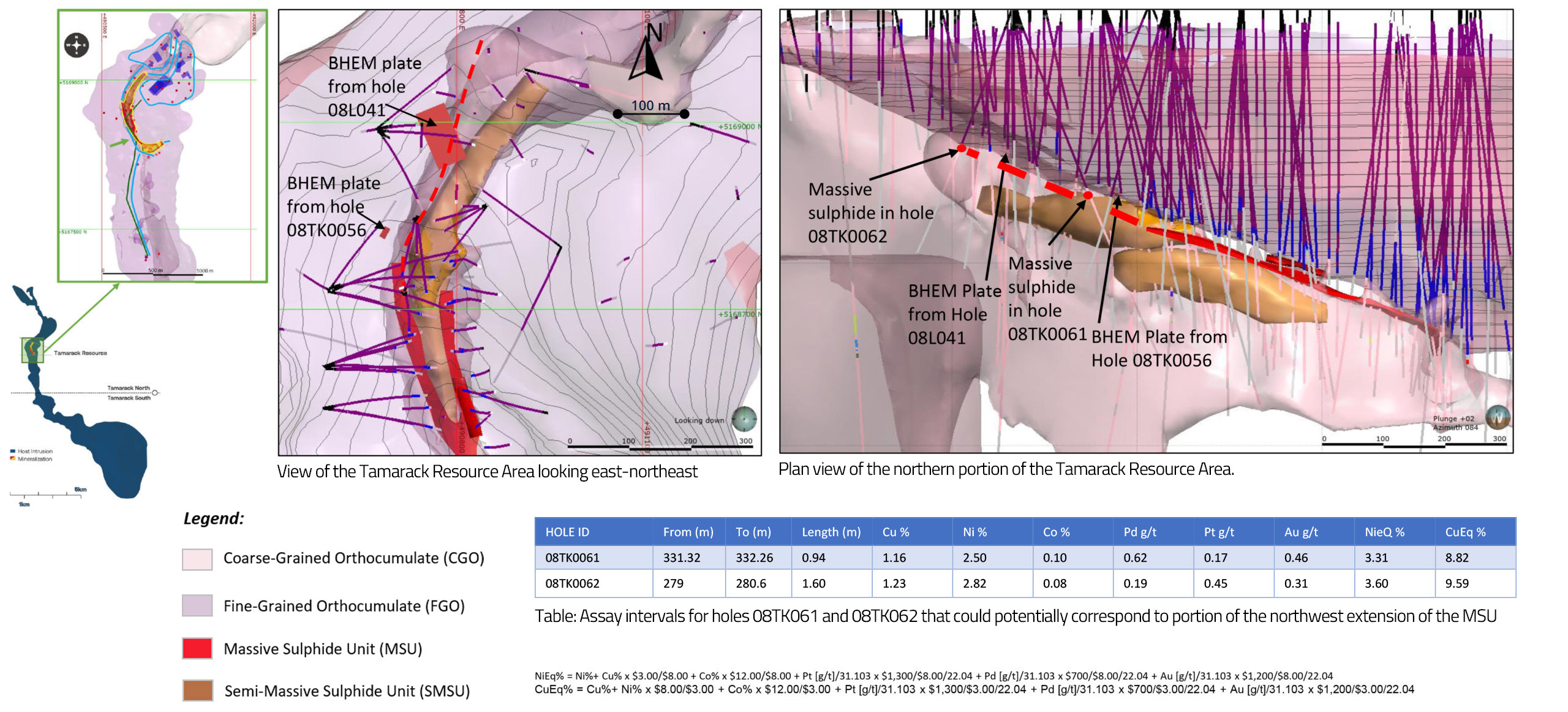

The Company has identified a new Borehole Electromagnetic (BHEM) from drill hole 16TK0250 that is located south of the current Massive Sulphide Unit (MSU) and is oriented roughly east-west (see figure below). The MSU has been interpreted to be composed of two parallel limbs straddling the CGO. The Company plans to test if the west MSU limb continues south (see dashed line on the figure below) and connect to a new BHEM plate. (See press release dated July 16, 2019)

MSU EXTENSION

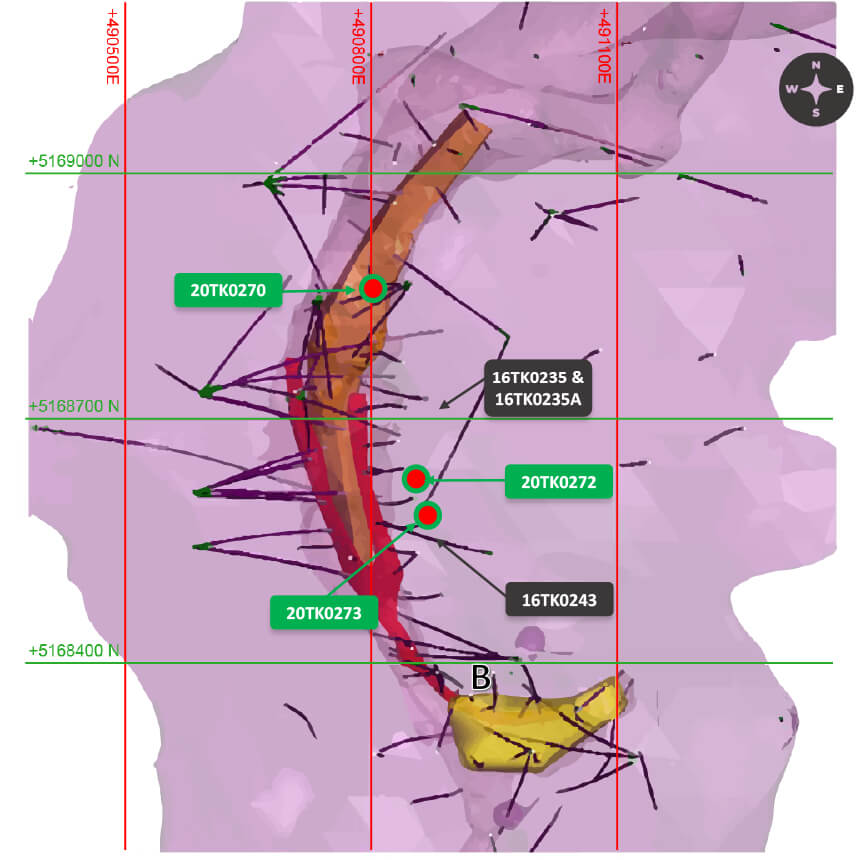

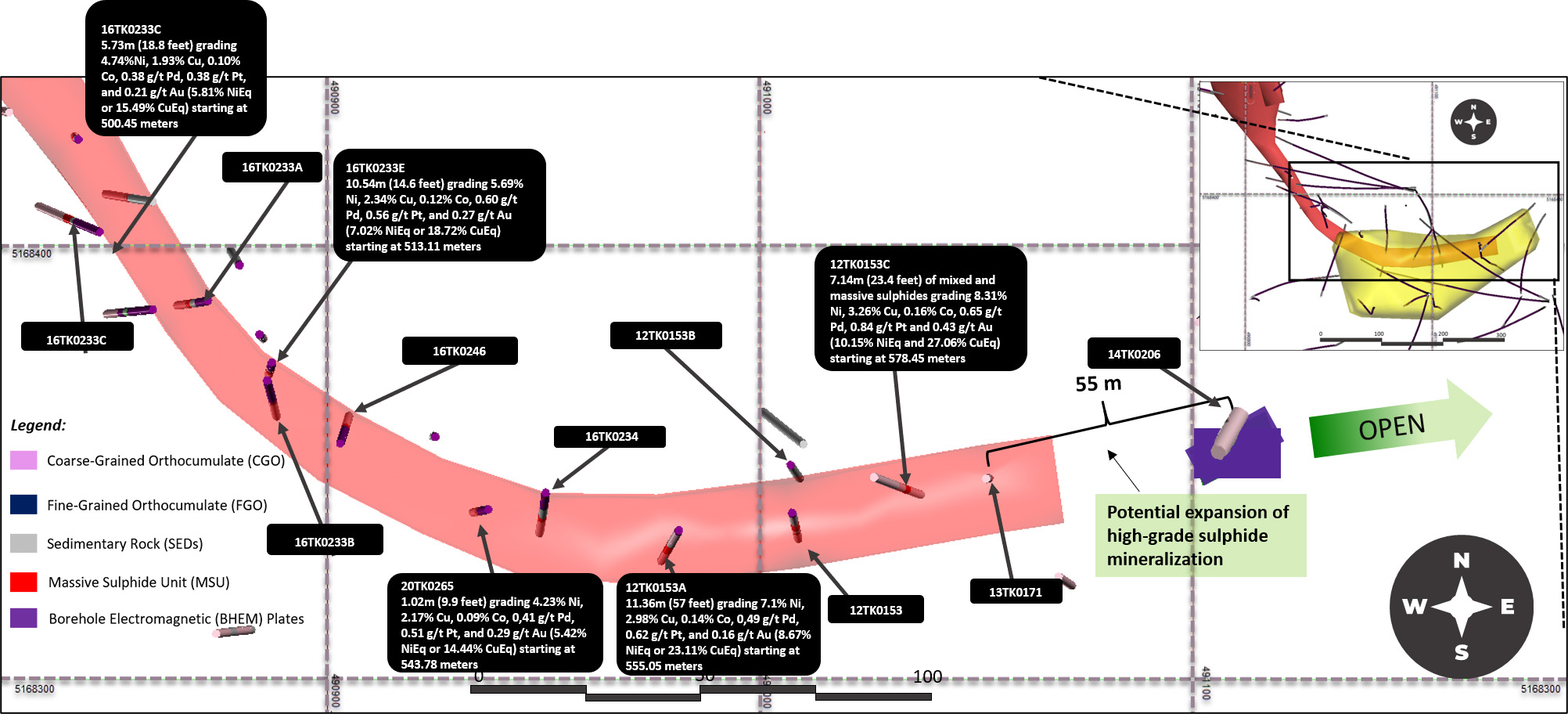

East MSU Extension

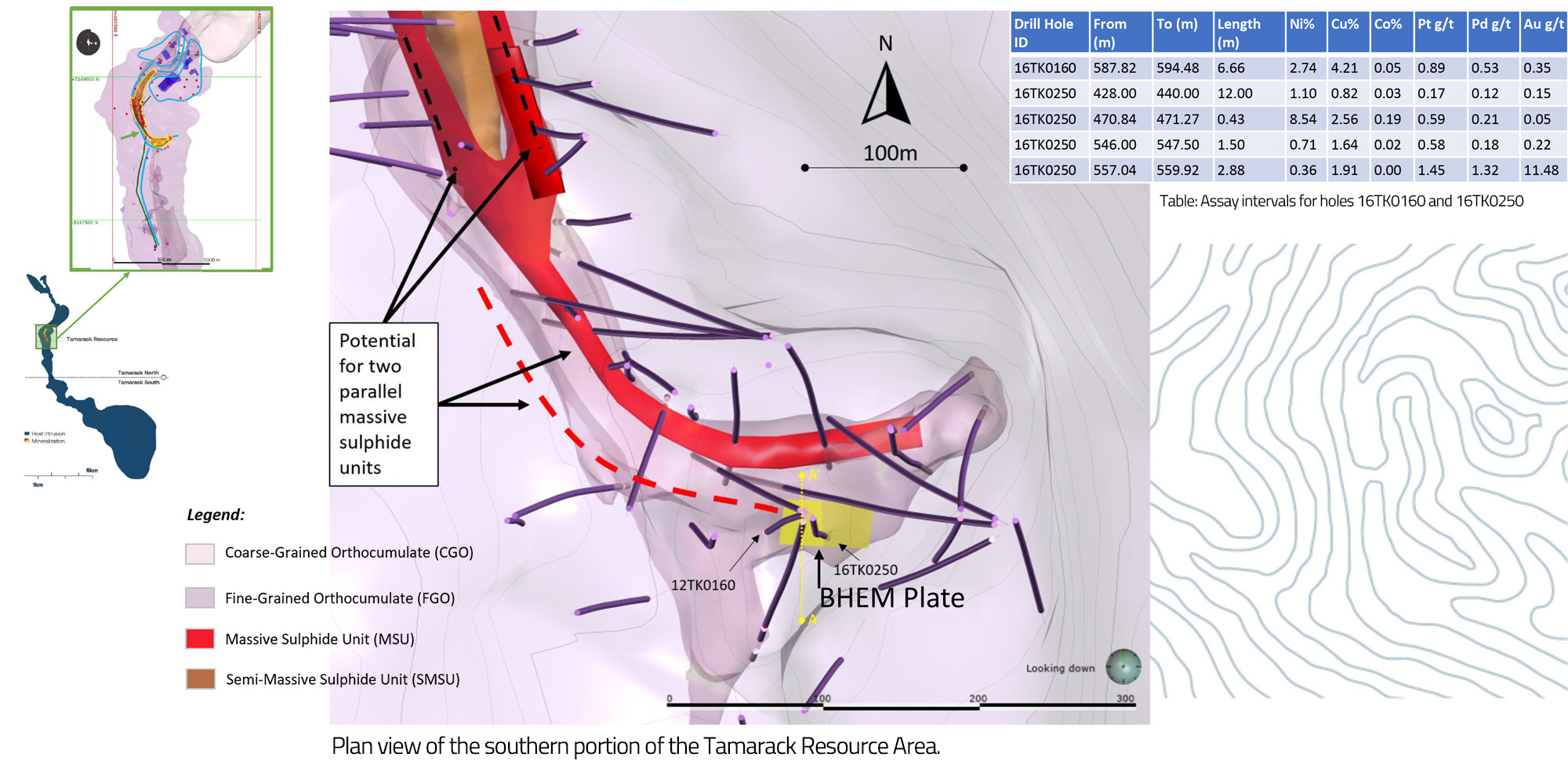

During Talon’s first exploration program (2020), the Company identified a borehole EM anomaly in drill hole 14TK0206 at a depth of 575 to 500 meters. The Company believes this area has the potential to represent an eastern extension of the MSU

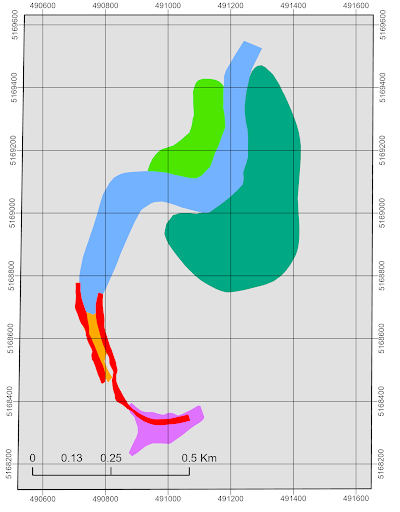

Plan view map of the southern portion of the Tamarack Resource Area, below the 138 Zone (also within the resource area). The map shows the location of the Winter 2020 Exploration Program drill holes with respect to the high-grade massive sulphide unit (MSU), including historical drill holes 12TK0153 and 13TK0171, and newly identified borehole EM anomaly from 575m to 600m depth.

- Drill hole 13TK0171 intersected 7.34 meters (24.1 feet) of MMS grading 8.28% Ni, 2.95% Cu, 0.15% Co, 0.55 g/t Pd, 0.39 g/t Pt and 0.19 g/t Au (9.81% NiEq or 26.06% CuEq) starting at 573.3 meters.

NiEq% = Ni%+ Cu% x $3.00/$8.00 + Co% x $12.00/$8.00 + Pt [g/t]/31.103 x $1,300/$8.00/22.04 + Pd [g/t]/31.103 x $700/$8.00/22.04 + Au [g/t]/31.103 x $1,200/$8.00/22.04

CuEq%ec = Cu%+ Ni% x $8.00/$3.00 + Co% x $12.00/$3.00 + Pt [g/t]/31.103 x $1,300/$3.00/22.04 + Pd [g/t]/31.103 x $700/$3.00/22.04 + Au [g/t]/31.103 x $1,200/$3.00/22.04

“In developing our Advanced Exploration System (AES), our in-house team of drillers, geophysicists, geologists, engineers and environmental scientists have materially increased our resource estimate while simultaneously upgrading a significant portion of the resource from the inferred to the indicated category in a short timeframe. Bringing these teams in-house has materially reduced costs and improved outcomes over the legacy practice of using outside contractors. This team is building a world leading environmentally responsible and cost-effective battery nickel and battery iron supply chain from mine-to-battery. Through our partnership with Tesla, this mine will produce battery minerals like nickel and iron for two different battery chemistries, ensuring that Tamarack has the highest ratio of kilowatt hours of battery storage per ton of ore,” van Rooyen commented.