MEDIA ADVISORY

News Release

TSX:TLO

FIRST DRILL RESULTS: TALON METALS INTERCEPTS 11.36 METERS (37 FEET) OF MIXED MASSIVE SULPHIDES GRADING 7.1% Ni, 2.98% Cu, 1.11 g/t PGEs, 0.16g/t Au AND 0.14% Co AT TAMARACK

Road Town, Tortola, British Virgin Islands (March 2, 2020) – Talon Metals Corp. (“Talon” or the “Company”) (TSX:TLO) is pleased to announce the first drill results from its winter 2020 exploration program at the Tamarack Nickel-Copper-Cobalt project (“Tamarack Project”), located in Minnesota, USA.

Highlights

- Drill hole 12TK0153A intercepted 36 meters (37 feet) of Mixed Massive Sulphides (“MMS”) (see Figure 1) grading 7.1% Ni, 2.98% Cu, 0.14% Co, 0.49 g/t Pd, 0.62 g/t Pt and 0.16 g/t Au (8.67% NiEq*) starting at 555.05 meters. Above this MMS intercept, an additional 130 meters (425 feet) of Mixed Zone mineralization (“MZNO”) has been logged, starting at 424.12 meters. Assays for the MZNO mineralization are pending.

FIGURE 1: DRILL CORE FROM DRILL HOLE 12TK0153A: PHOTO FROM ~554 METERS TO ~568 METERS

- In a second drill hole, being drill hole 20TK0265, the Company has also logged an additional 3.4 meters (11.2 feet) of MMS (see Figure 2) starting at 543.1 meters. Above this MMS intercept, an additional 118 meters (387.4 feet) of MZNO mineralization was also observed, starting at 422.61 meters. Assays for both intervals are pending

*NiEq% = Ni%+ Cu% x $3.00/$8.00 + Co% x $12.00/$8.00 + Pt [g/t]/31.103 x $1,300/$8.00/22.04 + Pd [g/t]/31.103 x $700/$8.00/22.04 + Au [g/t]/31.103 x $1,200/$8.00/22.04

FIGURE 2: DRILL CORE FROM DRILL HOLE 20TK0265

“Each drill hole has been designed to create significant value through better definition or extension of our mineral zones,” said Henri van Rooyen CEO of Talon Metals. “Drill hole 12TK0153A intercepted 7.1% nickel and 2.98% copper over 11.36 meters (37 feet) in an area where we had limited geological information and no borehole electromagnetic plates. Both the intercept width and grades of the MMS were better than planned.”

Drill Holes: Objectives, Design and Results

Drill Hole 12TK0153A

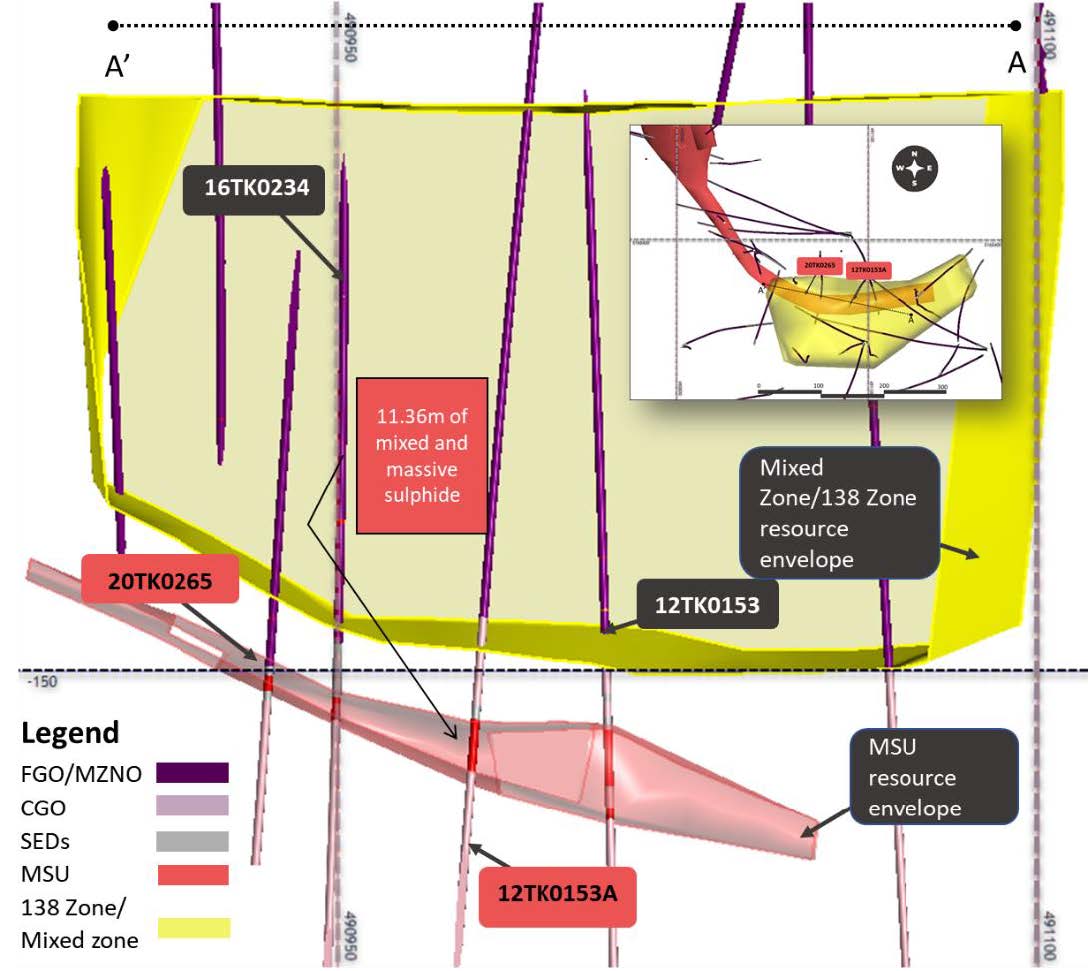

The primary objective of drill hole 12TK0153A was to test continuity of the high-grade Massive Sulphide Unit (“MSU”) between drill holes 12TK153 and 16TK0234, with the distance in between these drill holes being approximately 60 meters (196.9 feet).

Drill hole 12TK0153A was designed to intercept the MMS hosted by hornfelsed meta-sedimentary rocks between the Fine Grained Orthocumulate/Mixed Zone (“FGO/MZNO”) and Coarse Grained Orthocumulate (“CGO”). The lithological sequence was predicted to be similar to drill holes 12TK0153 and 12TK0171.

As a result, drill hole 12TK0153A intercepted 11.36 meters (37 feet) of MMS at the predicted elevation, approximately 30 meters (98.4 feet) to the east of drill hole 16TK0234 and 30 meters (98.4 feet) to the west of drill hole 12TK0153. Both the intercept width and grades of the MMS were higher than planned. Assays for the observed MZNO mineralization intercept of 130 meters (426.5 feet) above the MMS intercept are still pending.

Drill Hole 20TK0265

The objective of drill hole 20TK0265 was to test an area approximately 40 meters (131.2 feet) south-east of drill hole 16TK0246 and 22 meters (72.2 feet) to the west of drill hole 16TK0234.

Drill hole 20TK0265 was designed to intercept the MMS hosted by hornfelsed meta-sedimentary rocks between the FGO/MZNO and CGO with the expectation that the high-grade MSU should be narrower than drill hole 16TK0234, as it was predicted to be closer to the edge of the MSU. The drill hole was guided by targeting the edge of a borehole electromagnetic (“BHEM”) plate off drill hole 16TK0234.

As a result, an intercept of 3.4 meters (11.2 feet) of MMS has been logged at the predicted elevation which is in line with the Company’s expectations for this area. Assays for the MMS in drill hole 20TK0265 as well as the 118 meters (387.4 feet) of MZNO mineralization intercepted above the MMS are pending.

FIGURE 3: SECTION A-A’ LOOKING NORTH AND BELOW THE 138-ZONE. THE SECTION SHOWS THE LOCATION AND ELEVATION OF THE HIGH-GRADE MMS INTERSECTION IN DRILL HOLE 12TK0153A, DEMONSTRATING THE CONTINUITY OF THE HIGH-GRADE MSU WITH THE PREVIOUS HIGH-GRADE MMS INTERSECTIONS IN DRILL HOLE 16TK0234 AND HOLE 12TK0153. THE SECTION ALSO SHOWS THE LOCATION AND ELEVATION OF THE MMS INTERSECTION IN DRILL HOLE 20TK0265, DEMONSTRATING THE

CONTINUITY OF THE MSU WITH THE PREVIOUS HIGH-GRADE MMS INTERSECTIONS IN DRILL HOLES 16TK0246 AND 16TK0234

Measuring Accuracy of Intercepting Planned Drill Targets

The success of the Company’s winter program is dependent upon hitting drill targets at depth. A one degree deviation at surface could result in missing a drill target by 10 meters at a 580 meter depth.

“By using directional drilling, we have been able to save approximately 320 meters per drill hole, as we use the same parent hole to drill multiple branches to target depth. So far, we have consistently drilled within 3 meters of target, which we presently define through a combination of borehole electromagnetic and geological data,” said Brian Goldner, Head of Exploration at Talon on secondment from Rio Tinto.

The Company looks forward to providing additional results from further assays and geophysical data processing and interpretation when these become available.

Quality Assurance, Quality Control and Qualified Persons

Please see the technical report entitled “NI 43-101 Technical Report Preliminary Economic Assessment (PEA) of the Tamarack North Project – Tamarack, Minnesota” with an effective date of December 14, 2018 prepared by independent “Qualified Persons” (as that term is defined in National Instrument 43-101 (“NI 43-101”) Leslie Correia (Pr. Eng), Silvia Del Carpio (P. Eng.) Tim Fletcher (P. Eng.), Daniel Gagnon (P. Eng.), Kebreab Habte (P. Eng.), Oliver Peters (P. Eng.), Tom Radue (P. Eng.), and Brian Thomas (P. Geo.) for information on the QA/QC, analytical and testing procedures at the Tamarack Project. Copies are available on the Company’s website (www.talonmetals.com) or on SEDAR at (www.sedar.com). The laboratory used is ALS Minerals who is independent of the Company.

Lengths are drill intersections and not necessarily true widths. True widths cannot be consistently calculated for comparison purposes between holes because of the irregular shapes of the mineralized zones. Drill intersections have been independently selected by Talon. Drill composites have been independently calculated by Talon. The geological interpretations in this news release are solely those of the Company.

The locations and distances highlighted on all maps in this news release are approximate.

Dr. Etienne Dinel, Vice President, Geology of Talon, is a Qualified Person within the meaning of NI 43-101. Dr. Dinel is satisfied that the analytical and testing procedures used are standard industry operating procedures and methodologies, and he has reviewed, approved and verified the technical information disclosed in this news release, including sampling, analytical and test data underlying the technical information.

About Talon

Talon is a TSX-listed company focused on expanding its current NI 43-101 resource of high-grade nickel mineralization and identifying additional high-grade nickel mineralized zones. Talon is currently developing a process to potentially produce nickel sulphates responsibly for batteries for the electric vehicles industry within the United States. The high-grade Tamarack Nickel- Copper-Cobalt Project is located in Minnesota, USA, and comprises of the Tamarack North Project and the Tamarack South Project. The Company has a well-qualified exploration and mine management team with extensive experience in project management.

For additional information on Talon, please visit the Company’s website at www.talonmetals.com or contact:

Sean Werger

President

Talon Metals Corp.

Tel: (416) 361-9636 x102

Email: werger@talonmetals.com

Forward-Looking Statements

This news release contains certain “forward-looking statements”. All statements, other than statements of historical fact that address activities, events or developments that the Company believes, expects or anticipates will or may occur in the future are forward-looking statements. These forward-looking statements reflect the current expectations or beliefs of the Company based on information currently available to the Company. Such forward-looking statements include statements relating to the timing and results of the exploration program, including further assay results, geophysical data processing and interpretation and the ability to better define or extend the various mineral zones at the Tamarack Project. Forward-looking statements are subject to significant risks and uncertainties and other factors that could cause the actual results to differ materially from those discussed in the forward-looking statements, and even if such actual results are realized or substantially realized, there can be no assurance that they will have the expected consequences to, or effects on the Company.

Any forward-looking statement speaks only as of the date on which it is made and, except as may be required by applicable securities laws, the Company disclaims any intent or obligation to update any forward-looking statement, whether as a result of new information, future events or results or otherwise. Although the Company believes that the assumptions inherent in the forward- looking statements are reasonable, forward-looking statements are not guarantees of future performance and accordingly undue reliance should not be put on such statements due to the inherent uncertainty therein.

Table 1: Collar Locations of Reported Drill Holes

HOLEID | Easting (m) | Northing (m) | Elevation (masl) | Wedge depth (m) |

Azm |

Dip | End Depth |

12TK0153 | 490982 | 5168405 | 388.36 |

320.0 | 161.1 | -82.3 | 683.67 |

12TK0153A | 490982 | 5168405 | 388.36 | 174.5 | -81.8 | 614.00 | |

16TK0234 | 490949 | 5168389 | 388.44 | 180.6 | -85.1 | 696.77 | |

20TK0265 | 490949 | 5168389 | 388.44 | 174.0 | -82.6 | 584.00 |

Collar coordinates are UTM Zone 15N, NAD83.

Azimuth and Dip are downhole survey averages for the hole.

For daughter holes; collar coordinates and elevations are same as mother hole; approximate wedge depth given; azimith and dip are the survey averages below the wedge.

Table 2: Assay Results: Drill Hole 12TK153A

BHID | From | To | Length | % Cu | % Ni | % Co | Pt g/t | Pd g/t | Au g/t | NiEq |

12TK0153A | 555 | 566.36 | 11.36 | 2.98 | 7.10 | 0.14 | 0.62 | 0.49 | 0.16 | 8.67 |

including | 561.25 | 562.03 | 0.78 | 4.74 | 8.39 | 0.17 | 0.10 | 0.65 | 0.19 | 10.57 |

including | 563.54 | 564.03 | 0.49 | 2.26 | 9.28 | 0.19 | 0.08 | 0.60 | 0.03 | 10.52 |

Length refers to drill hole length and not True Width. True Width is unknown at the time of publication.

All samples were analysed by ALS Minerals. Nickel, copper, and cobalt grades were first analysed by a 4-acid digestion and ICP AES (ME-MS61). Grades reporting greater than 0.25% Ni and/or 0.1% Cu, using ME-MS61, trigger a sodium peroxide fusion with ICP-AES finish (ICP81). Platinum, palladium and gold are initially analyzed by a 50g fire assay with an ICP-MS finish (PGM-MS24). Any samples reporting >1g/t Pt or Pd trigger an over-limit analysis by ICP-AES finish (PGM-ICP27) and any samples reporting >1g/t Au trigger an over- limit analysis by AAS (Au-AA26).

NiEq% = Ni%+ Cu% x $3.00/$8.00 + Co% x $12.00/$8.00 + Pt [g/t]/31.103 x $1,300/$8.00/22.04 + Pd [g/t]/31.103 x $700/$8.00/22.04 + Au [g/t]/31.103 x $1,200/$8.00/22.04