MEDIA ADVISORY

News Release

TSX:TLO

TALON METALS COMMENCES DRILL PROGRAM AT TAMARACK

Road Town, Tortola, British Virgin Islands (January 21, 2020) – Talon Metals Corp. (“Talon” or the “Company”) (TSX: TLO) is pleased to announce the commencement of its exploration program at the Tamarack Nickel-Copper-Cobalt project (“Tamarack Project”), located in Minnesota, USA. The Tamarack Project comprises the Tamarack North Project and the Tamarack South Project.

Talon is well funded to execute on its exploration program with over C$7 million in its treasury. The Company has mobilized three drill rigs in respect of its program at Tamarack.

The Company’s principal objectives for the exploration program are to:

- Better define the high-grade mineralized zone, known as the Massive Sulphide Unit (“MSU”), by converting resources from the inferred category to the indicated category, with the goal of progressing the Tamarack Project towards the pre- feasibility study stage; and

- Utilize various geophysical techniques to identify drill targets for the purpose of extending (growing) the high grade MSU, and then begin drilling these targets as part of this exploration

“The nickel grades of the massive sulphide unit at Tamarack are high, even when compared to other high grade nickel, copper and cobalt projects globally. Our first order of business for 2020 is to better define and potentially expand the high grade massive sulphide unit as we progress the project towards a pre-feasibility study,” said Henri van Rooyen, Talon CEO.

“We are one of a few mineral exploration projects with capital to potentially create significant value by following up on possible high grade massive sulphide extensions, while at the same time moving the Tamarack Project towards the pre-feasibility stage. We look forward to updating shareholders as and when results become available in the coming weeks,” said Sean Werger, Talon President.

(A) Better Defining the High Grade MSU: Progressing Towards a Pre-feasibility Study by Converting Resources from the Inferred Category to the Indicated Category

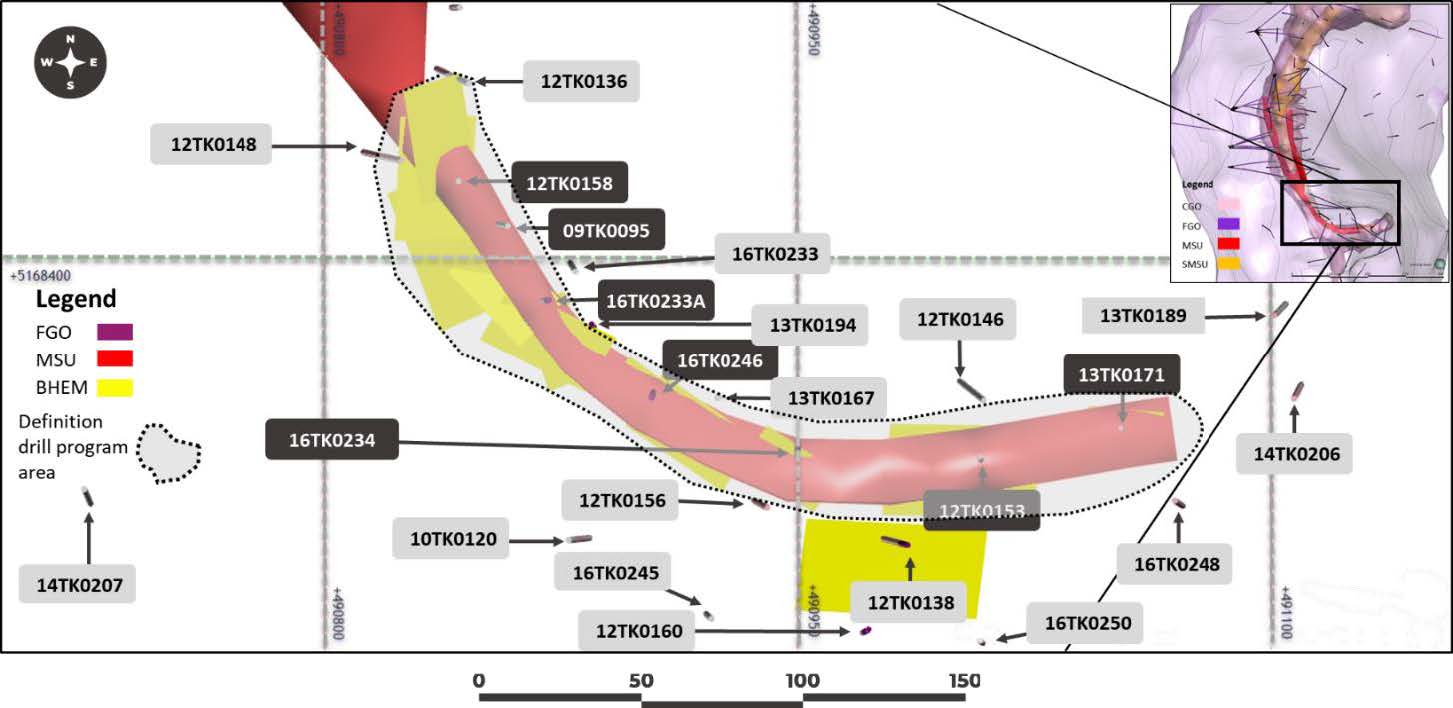

Talon has mobilized three drill rigs to the Tamarack North Project to commence an in-fill (definition) drilling program, which is expected to continue from January to March 2020. The program is utilizing directional drilling to target up to 10 daughter drill holes from three parent holes. The plan is to step-out between 20 to 30 meters from existing drill holes, with an intention of showing continuity of high-grade mineralization. If each hole was to be drilled from surface, the total meterage drilled would be approximately 6,500 meters. With directional drilling, Talon plans to achieve the same objective with 2,500 meters of drilling. Drill hole azimuth and dip is set to target modeled Borehole Electromagnetic (“BHEM”) plates as shown in Figure 1.

FIGURE 1: PLAN VIEW SHOWING THE SECTION OF THE MASSIVE SULPHIDE UNIT (SEE DOTTED LINES) THAT THE COMPANY PLANS TO DRILL TO CONVERT RESOURCES FROM THE INFERRED TO THE INDICATED CATEGORY

(B) Extending (Growing) the High-Grade Zone: Following the High-Grade MSU Trajectory (Going East)

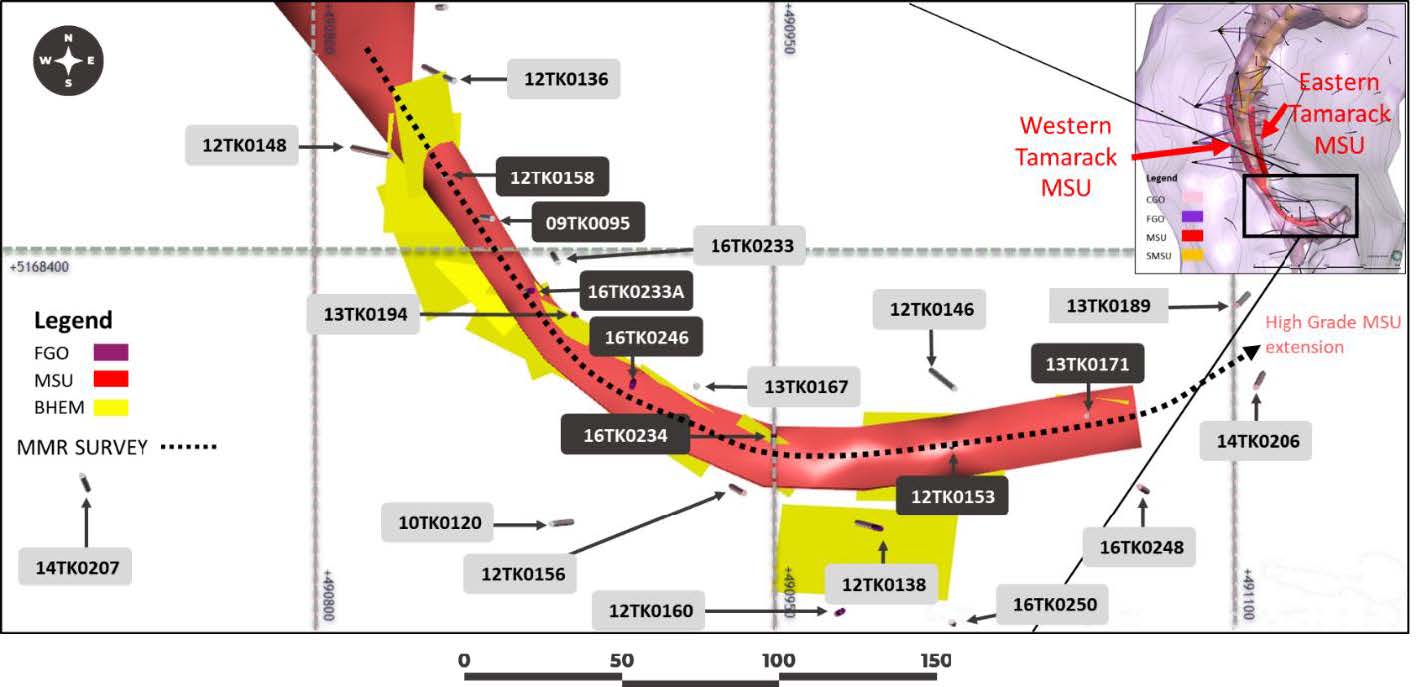

As described in Talon’s press release dated June 3, 2019, as part of a number of geophysical techniques being utilized at the Tamarack Project, Talon is conducting a magnetometric resistivity (“MMR”) survey to confirm the results of a previous MMR survey, which indicated that the high grade MSU may be continuing to the east (see Figure 2). The MMR survey is expected to be completed in January 2020, followed by data processing, interpretation and evaluation of a possible drill target. Drilling of confirmed targets is expected to follow in February 2020, with the intention of growing the high grade MSU to the east.

FIGURE 2: PLAN VIEW SHOWING THE POSSIBLE CONTINUATION OF THE HIGH GRADE MSU USING MAGNETOMETRIC RESISTIVITY (SEE DOTTED LINE AND ARROW)

(C) Extending (Growing) the High Grade Zone: Looking for a Possible Continuation of the High Grade MSU (Going West)

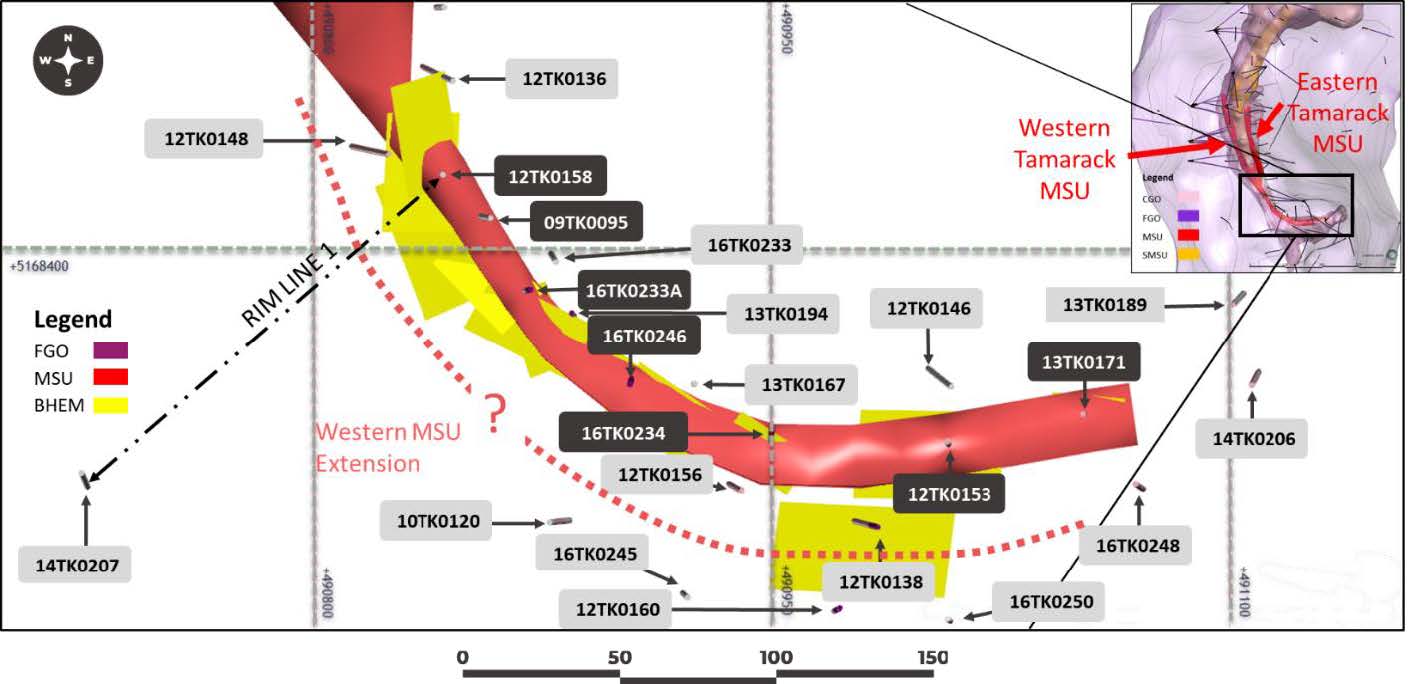

A Radio Imaging (“RIM”) survey is also planned during January 2020. The objective is to determine if the western high grade MSU continues parallel to the eastern high grade MSU as shown in Figure 3. Once the data has been processed and interpreted, a decision to drill will be formulated. Drilling of confirmed targets is expected to follow in February 2020, with the intention of growing the high grade MSU.

FIGURE 3: PLAN VIEW TO DETERMINE IF THE WESTERN HIGH GRADE MSU CONTINUES PARALLEL TO THE EASTERN HIGH GRADE MSU (SEE RED DOTTED LINE)

“The present geophysical program at the Tamarack Project has a dual purpose: first, to effectively expand and better define the high grade massive sulphide unit and second, to test new geophysical survey techniques over known high grade massive sulphide mineralization at the Tamarack Project. Assuming these geophysical techniques are proven to work at Tamarack, they could then be used in future exploration programs to cost effectively follow-up on massive sulphide intercepts over great distances with the objective of making new discoveries along the approximate 18-kilometer Tamarack Intrusive Complex” said Talon Geophysicist and Consultant, Brian Bengert.

Quality Assurance, Quality Control and Qualified Persons

Please see the technical report entitled “NI 43-101 Technical Report Preliminary Economic Assessment (PEA) of the Tamarack North Project – Tamarack, Minnesota” with an effective date of December 14, 2018 prepared by independent “Qualified Persons” (as that term is defined in National Instrument 43-101 (“NI 43-101”) Leslie Correia (Pr. Eng), Silvia Del Carpio (P. Eng.) Tim Fletcher (P. Eng.), Daniel Gagnon (P. Eng.), Kebreab Habte (P. Eng.), Oliver Peters (P. Eng.), Tom Radue (P. Eng.), and Brian Thomas (P. Geo.) for information on the QA/QC, analytical and testing procedures at the Tamarack Project. Copies are available on the Company’s website (www.talonmetals.com) or on SEDAR at (www.sedar.com). The laboratory used is ALS Minerals who is independent of the Company.

The locations and distances highlighted on all maps in this news release are approximate.

Dr. Etienne Dinel, Vice President, Geology of Talon, is a Qualified Person within the meaning of NI 43-101. Mr. Dinel is satisfied that the analytical and testing procedures used are standard industry operating procedures and methodologies, and he has reviewed, approved and verified the technical information disclosed in this news release, including sampling, analytical and test data underlying the technical information.

About Talon

Talon is a TSX-listed company focused on expanding its current NI 43-101 resource of high grade nickel mineralization; identifying additional high grade nickel mineralization; and developing a process to potentially produce nickel sulphates responsibly for batteries for the electric vehicles industry all within the United States. The high grade Tamarack Nickel-Copper-Cobalt Project is located in Minnesota, USA, and comprises of the Tamarack North Project and the Tamarack South Project. The Company has a well-qualified exploration and mine management team with extensive experience in project management.

For additional information on Talon, please visit the Company’s website at www.talonmetals.com or contact:

Sean Werger

President

Talon Metals Corp.

Tel: (416) 361-9636 x102

Email: werger@talonmetals.com

Telephone: 416-361-9636

Forward-Looking Statements

This news release contains certain “forward-looking statements”. All statements, other than statements of historical fact that address activities, events or developments that the Company believes, expects or anticipates will or may occur in the future are forward-looking statements. These forward-looking statements reflect the current expectations or beliefs of the Company based on information currently available to the Company. Such forward-looking statements include statements relating to the exploration program, including (i) plans to better define the high grade MSU and the potential to convert resources from the inferred category to the indicated category, (ii) plans to grow the high grade MSU to the east, and (iii) the possible continuation of the high grade MSU to the west and the timing of the exploration program and the results thereof. Forward-looking statements are subject to significant risks and uncertainties and other factors that could cause the actual results to differ materially from those discussed in the forward-looking statements, and even if such actual results are realized or substantially realized, there can be no assurance that they will have the expected consequences to, or effects on the Company.

Any forward-looking statement speaks only as of the date on which it is made and, except as may be required by applicable securities laws, the Company disclaims any intent or obligation to update any forward-looking statement, whether as a result of new information, future events or results or otherwise. Although the Company believes that the assumptions inherent in the forward- looking statements are reasonable, forward-looking statements are not guarantees of future performance and accordingly undue reliance should not be put on such statements due to the inherent uncertainty therein.

Table 1: Collar location for drill hole 10TK0120 (not previously publicly disclosed)

| Drill Hole ID | Easting | Northing | Elevation | Azimuth | Dip | Length |

| 10TK0120 | 490805.3 | 5168289 | 388.447 | 62.09 | 83.24 | 676.66 |

Table 2: Assay results for drill hole 10TK0120 (not previously publicly disclosed)

| Drill Hole ID | From (m) | To (m) | Length (m) | Ni % | Cu % | Co % | Pt g/t | Pd g/t | Au g/t |

| 10TK0120 | No Significant sulphides | ||||||||

NSM: No Significant Mineralization

Length refers to drill hole length and not True Width. True Width is unknown at the time of publication.

All samples were analysed by ALS Minerals. Nickel, copper, and cobalt grades were first analysed by a 4-acid digestion and ICP AES (ME-MS61). Grades reporting greater than 0.25% Ni and/or 0.1% Cu, using ME-MS61, trigger a sodium peroxide fusion with ICP-AES finish (ICP81). Platinum, palladium and gold are initially analyzed by a 50g fire assay with an ICP-MS finish (PGM-MS24). Any samples reporting >1g/t Pt or Pd trigger an over-limit analysis by ICP-AES finish (PGM-ICP27) and any samples reporting >1g/t Au trigger an over-limit analysis by AAS (Au-AA26).