MEDIA ADVISORY

News Release

TSX:TLO

TALON METALS UPDATE: CONSIDERATION GIVEN TO A PHASE 1, DIRECT SHIPPING ORE (DSO) OPTION OF THE MASSIVE SULPHIDE UNIT (MSU)

Road Town, British Virgin Islands (May 9, 2019) – Talon Metals Corp. (“Talon” or the “Company”) (TSX: TLO) is pleased to provide an update on the Tamarack high-grade nickel-copper-cobalt project (the “Tamarack Project”), located in Minnesota, USA. The Tamarack Project comprises the Tamarack North Project and the Tamarack South Project.

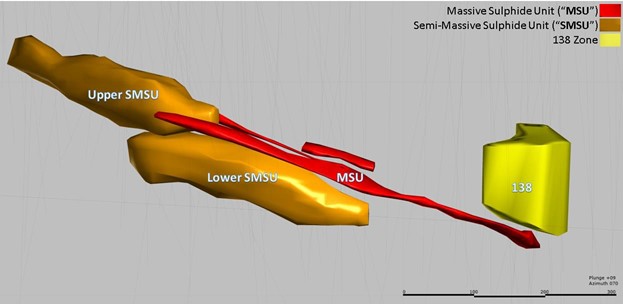

As part of the progression of the project through to the next key study phase, and due to the high-grade nature and spatial separation of the Massive Sulphide Unit (“MSU” – Figure 1), Talon is considering multiple options, including (i) shipping the MSU for offsite processing; and (ii) blending the MSU with other mineralization types for onsite processing.

“Given the strategic nature of the Tamarack high grade Ni-Cu-Co Project we are studying a multitude of options. Shipping the MSU for offsite processing is one option which could potentially reduce upfront capex and time to production, as there will not be a need for a concentrator on site,” said Henri van Rooyen, CEO of Talon. “We expect that this process would not sterilize ore. Direct Shipping Ore (DSO) may generate net cash to contribute to the construction of an onsite concentrator to process the other types of mineralization. As part of our decision-making process, Talon plans to also evaluate the impact of blending all mineralization types, including the MSU, on the quality of concentrates.”

“Talon may have the option to sell its nickel concentrates to smelters and/or partner with downstream battery metal facilities for producing battery precursor materials, which may materially reduce the cost of Lithium-ion batteries and consequently, electric vehicles,” said Sean Werger, President of Talon. “Talon will complete the necessary studies to determine the best path forward.”

Talon is committed to the responsible mining and production of nickel for Electric Vehicles (“EV”). As a first step to evaluating different options, the Company has commissioned two pre-concentration amenability studies to take advantage of the density differences between sulphide minerals and gangue. Pre-concentration typically results in a net capex, energy and consequently a reduction in opex:

Capex reduction: Less tonnage to the mill could reduce the mill size and therefore, the net capex;

Reduction of opex:

- Milling requires high energy; therefore, an increase in grade and consequently, a reduction in mill tonnage, will require less energy;

- Hardness of the pre-concentrated material may be reduced resulting in further energy reduction; and

- Pre-concentration could remove deleterious elements, thereby reducing the use of re-agents in the flotation

Spatial Separation of the MSU from the other Mineral Zones: No Sterilization

Due to the MSU’s spatial separation from the other mineral zones, the MSU could potentially be mined first, without sterilizing the other mineral zones – see Figure 1 below.

Figure 1: Oblique east-north-east view of the Tamarack North Project mineral zones. Drilling and mining the MSU may not sterilize the other mineral zones.

Description of Test Work

Pre-concentration amenability test work is underway to evaluate if two styles of mineralization found in the Tamarack North Project could be upgraded by Dense Media Separation (“DMS”) on a commercial scale. Heavy Liquid Separation (“HLS”) testing will therefore be performed, which simulates DMS performance on a laboratory scale.

Test Program 1: Removal of meta-sedimentary rocks from the MSU prior to milling and flotation

The first test program is focusing on the Mixed Massive Sulphide (“MMS”), which is a combination of MSU and intervals of meta-sedimentary rocks – see Figure 2 below. The density contrast between these units is high and therefore, HLS testing is expected to differentiate between the sulphides and gangue, thereby potentially decreasing tonnage to the mill while at the same time having the potential to increase grade.

Figure 2: Image showing Metasediment and Mixed Massive Sulphide (MMS) units from drill hole 13TK0171, from 573.3m to 580.8 meters depth

Test Program 2: Removal of silicate minerals from the coarse-grained ortho-cumulative (“CGO”) intrusion prior to milling and flotation

The second test program is focused on the low grade disseminated sulphides in the CGO, which tend to be relatively coarse and patchy in texture – see Figure 3 below. HLS will be tested given the density contrast between the sulphide and silicate minerals. The objective is to reject most of the silicate minerals.

Figure 3: 1.5m sample interval, from 406m depth to 407.5m depth in drill hole 16TK0242, was broken down into a ¼” grid and marked where sulphide minerals were visually observed

Possible Impact on Future Exploration Programs

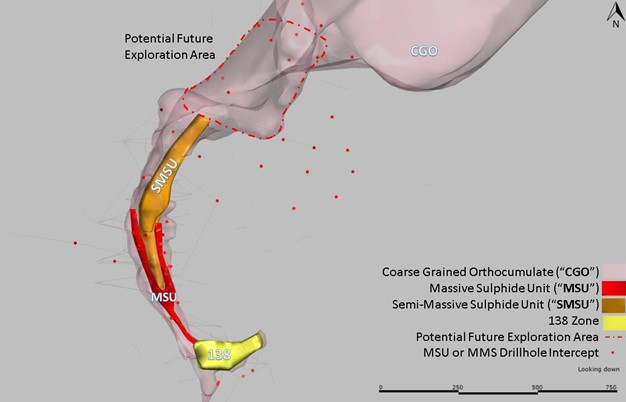

If low-grade mineralization can be pre-concentrated to above cut-off grades, future exploration at the Tamarack North Project may also focus on a large area of CGO mineralization as shown in Figure 4 below.

Figure 4: Tamarack North Project mineral zones: Looking down (plan view). A large area of CGO mineralization that could be considered for future exploration is outlined using a red dash line. Red dots are MSU and/or MMS intercepts.

Transportation Studies

The Tamarack Project is located on infrastructure. Talon has partnered with Krech Ojard & Associates, Consulting Engineers of Duluth Minnesota to develop optimal transport solutions for both the MSU and separate nickel and copper sulphide concentrates.

Qualified Person and Technical Disclosure

Please see the technical report entitled “NI 43-101 Technical Report Preliminary Economic Assessment (PEA) of the Tamarack North Project – Tamarack, Minnesota” with an effective date of December 14, 2018 prepared by independent “Qualified Persons” (as that term is defined in NI 43-101) Leslie Correia (Pr.Eng), Silvia Del Carpio (P. Eng.) Tim Fletcher (P. Eng.), Daniel Gagnon (P. Eng.), Kebreab Habte (P. Eng.), Oliver Peters (P. Eng.), Tom Radue (P. Eng.), and Brian Thomas (P. Geo.) for information on the QA/QC, analytical and testing procedures at the Tamarack Project. Copies are available on the Company’s website (www.talonmetals.com) or on SEDAR at (www.sedar.com). The laboratory used is ALS Minerals who is independent of the Company.

Drill intersections have been independently selected by Talon. Drill composites have been independently calculated by Talon. The geological interpretations in this news release are solely those of the Company.

The locations and distances highlighted on all maps in this news release are approximate.

Oliver Peters, Mineral Processing Engineer, is a Qualified Person within the meaning of NI 43-

Mr. Peters has reviewed, approved and verified the technical information disclosed in this news release, including sampling, analytical and test data underlying the technical information.

About Talon

Talon is a TSX-listed company focused on producing nickel responsibly for the electric vehicle industry. The high-grade Tamarack Ni-Cu-Co Project is located in Minnesota, USA (which comprises the Tamarack North Project and the Tamarack South Project). The Company has a well-qualified exploration and mine management team with extensive experience in project management. For additional information on Talon, please visit the Company’s website at www.talonmetals.com or contact:

Sean Werger

President

Talon Metals Corp.

Tel: (416) 361-9636 x102

Email: werger@talonmetals.com

Forward-Looking Statements

This news release contains certain “forward-looking statements”. All statements, other than statements of historical fact that address activities, events or developments that the Company believes, expects or anticipates will or may occur in the future are forward-looking statements. These forward-looking statements reflect the current expectations or beliefs of the Company based on information currently available to the Company. Such forward-looking statements include statements relating to the possible direct shipping of material, the effect of blending the MSU, potential reduction in capex, opex and time to production and possible increased recoveries, the sale of nickel concentrates, the results of the pre-concentration studies and test work, mining MSU and the future exploration of the Tamarack Project. Forward-looking statements are subject to significant risks and uncertainties and other factors that could cause the actual results to differ materially from those discussed in the forward-looking statements, and even if such actual results are realized or substantially realized, there can be no assurance that they will have the expected consequences to, or effects on the Company.

Any forward-looking statement speaks only as of the date on which it is made and, except as may be required by applicable securities laws, the Company disclaims any intent or obligation to update any forward-looking statement, whether as a result of new information, future events or results or otherwise. Although the Company believes that the assumptions inherent in the forward- looking statements are reasonable, forward-looking statements are not guarantees of future performance and accordingly undue reliance should not be put on such statements due to the inherent uncertainty therein.