MEDIA ADVISORY

News Release

TSX:TLO

TALON METALS ANNOUNCES IMPROVED ECONOMICS UNDER ITS UPDATED PEA AND A 106% INCREASE IN OVERALL TONNAGE INCLUDED IN THE MINE PLAN, ALONG WITH AN INCREASED MINE LIFE

Road Town, Tortola, British Virgin Islands (March 5, 2020) – Talon Metals Corp. (“Talon” or the “Company”) (TSX:TLO) is pleased to announce that it has completed an updated Preliminary Economic Assessment (the “Updated PEA“) over a subset of the mineral resource estimate within the Tamarack Zone (located at the Tamarack North Project, Minnesota, USA). Talon currently has the right to acquire up to a 60% ownership interest in the Tamarack Project on the satisfaction of certain terms and conditions. All amounts are presented on a 100% ownership basis and all dollar amounts are in United States dollars.

Highlights

- The overall tonnage included in the mine plan has increased by 106% from the Initial PEA1 to 4.91 million tonnes under the Updated PEA;

- After-tax NPV has increased by 39% from the Initial PEA to US$291M under the Updated PEA (using a discount rate of 7%);

- Excellent after-tax IRR of 36% at base case metal prices;

- Low C1 cost of US$2.67 per lb of nickel in concentrate2;

- Overall nickel and copper grades remain high at 2.10% and 1.06%, respectively, with a Nickel Equivalent (NiEq)3 grade of 82%;

- Total nickel and copper recoveries remain high at 83.4% and 94.4%, respectively;

- Initial and total CAPEX remains low at US$219M and US$259M, respectively;

1 See the independent technical report entitled “NI 43-101 Technical Report Preliminary Economic Assessment (PEA) of the Tamarack North Project – Tamarack, Minnesota” with an effective date of December 14, 2018 (the “Initial PEA”) available on the Company’s website (www.talonmetals.com) and SEDAR (www.sedar.com)

2 C1 cost includes value of metal claimed by smelter (metal units, treatment charges and refining charges), insurance, losses and transportation costs, less the value of by-products such as copper and cobalt. C1 cost is not an IFRS (International Financial Reporting Standards) measure and, although it is calculated according to accepted industry practice, the C1 cost may not be directly comparable to calculations carried out by other companies.

3 NiEq% = Ni%+ Cu% x $3.00/$8.00 + Co% x $25.00/$8.00 + Pt [g/t]/31.103 x $1,000/$8.00/22.04 + Pd [g/t]/31.103 x

$1,000/$8.00/22.04 + Au [g/t]/31.103 x $1,300/$8.00/22.04

- Mine life has increased from 6.4 years under Initial PEA to 7.5 years under the Updated PEA, combined with a mill treatment capacity increase from 1,390 tpd to 2,000 tpd; and

- Quick after-tax payback of 2.5

“The Updated PEA demonstrates that by conducting additional metallurgical test work, and thereby adding tonnage into the mine plan (with no additional drilling), the economics associated with the Tamarack North Project keep improving significantly, despite the fact that they were excellent to begin with”, said Henri van Rooyen, CEO of Talon. “Nonetheless, additional opportunities still remain to further increase the tonnage included in the mine plan and consequently, the mine life and production rate.”

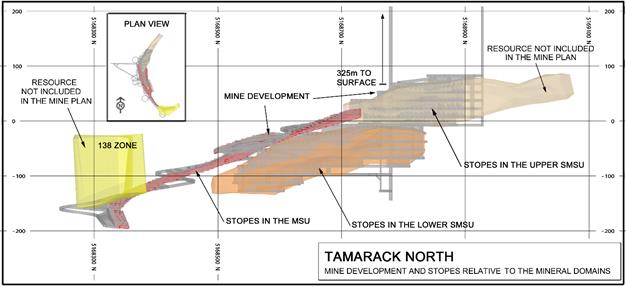

Figure 1: Long Section (looking west) of the Updated PEA Conceptual Mine Plan Development and Stopes in Relation to the Wireframes for Resource Domains

Mineral Resource Estimate

On March 26, 2018, Talon published a technical report (the “March 2018 Technical Report”) that provided an updated independent mineral resource estimate (effective date of February 15, 2018), which was used as the basis for the Updated PEA.

Table 1: Tamarack North Resource Estimate: Effective February 15, 2018

Domain | Resource Classification | Tonnes (000) | Ni (%) | Cu (%) | Co (%) | Pt (g/t) | Pd (g/t) | Au (g/t) | *Calc NiEq (%) |

SMSU | Indicated Resource | 3,639 | 1.83 | 0.99 | 0.05 | 0.42 | 0.26 | 0.2 | 2.45 |

Total | Indicated Resource | 3,639 | 1.83 | 0.99 | 0.05 | 0.42 | 0.26 | 0.2 | 2.45 |

SMSU | Inferred Resource | 1,107 | 0.90 | 0.55 | 0.03 | 0.22 | 0.14 | 0.12 | 1.25 |

MSU | Inferred Resource | 570 | 5.86 | 2.46 | 0.12 | 0.68 | 0.51 | 0.25 | 7.24 |

138 Zone | Inferred Resource | 2,705 | 0.95 | 0.74 | 0.03 | 0.23 | 0.13 | 0.16 | 1.38 |

Total | Inferred Resource | 4,382 | 1.58 | 0.92 | 0.04 | 0.29 | 0.18 | 0.16 | 2.11 |

All resources reported at a 0.83% NiEq cut-off.

No modifying factors have been applied to the estimates. Tonnage estimates are rounded to the nearest 1,000 tonnes. Metallurgical recovery factored into the reporting cut-off.

*NiEq% = Ni%+ Cu% x $3.00/$8.00 + Co% x $12.00/$8.00 + Pt [g/t]/31.103 x $1,300/$8.00/22.04 + Pd [g/t]/31.103 x $700/$8.00/22.04 + Au [g/t]/31.103 x $1,200/$8.00/22.04.

Updated PEA Results

The basis of design of the Updated PEA, which was completed on a portion of the upper SMSU, the lower SMSU and the MSU are summarized in Table 2 below. The Updated PEA is preliminary in nature. The Updated PEA includes inferred mineral resources. Inferred mineral resources are considered too speculative geologically to have economic considerations applied to them that would enable them to be categorized as mineral reserves. There is no certainty that the Updated PEA will be realized.

Table 2: Basis of Design: Updated PEA*

No | Parameter | Description |

1 | Approach and Mandate | Implement Best Available Technologies to protect the environment while creating a catalyst for establishing long-term, sustainable industry |

2 | Mine Access Method | 5 meter Diameter Shaft |

3 | Mine Methods | Transverse Drift-and-Fill (MSU) and Transverse Open Stoping (SMSU) |

4 | Type of Metallurgical Process | Bulk rougher flotation followed by cleaning of the bulk rougher concentrate and Cu/Ni separation |

5 | Separation of Tailings | Bulk rougher tailings are treated in a desulphurization stage to produce a low- mass high sulphur stream and high-mass low sulphur tailings |

6 | Backfill | Cemented paste backfill in a primary-secondary sequence utilizing all high sulphur and 45% of low sulphur tailings |

7 | Co-disposed Filtered Tailings Facility (“CFTF”) | Filtered low sulphur tailings (at 85% solids) will be co-disposed with waste rock in a lined surface facility. The liner system of the facility will consist of a composite liner overlain by a drainage layer. Contact water from the facility will be collected using a perimeter ditch and conveyed to a water treatment plant. Upon closure, the CFTF will be encapsulated by a composite cover. |

8 | Life of Mine (“LOM”) Feed** | SMSU Indicated: 3.362 mt at 1.92% Ni, 1.03% Cu, 0.05% Co, 0.41 g/t Pt, 0.26 g/t Pd, 0.20 g/t Au, 2.62% NiEq∆ SMSU Inferred: 0.515 mt at 1.11% Ni, 0.65% Cu, 0.03% Co, 0.20 g/t Pt, 0.13 g/t Pd, 0.11 g/t Au, 1.54% NiEq∆ MSU Inferred: 0.563 mt at 5.88% Ni, 2.47% Cu, 0.12% Co, 0.51 g/t Pt, 0.68 g/t Pd, 0.24 g/t Au, 7.45% NiEq∆ Total Inferred: 1.077 mt at 3.60% Ni, 1.60% Cu, 0.08% Co, 0.36 g/t Pt, 0.41 g/t Pd, 0.18 g/t Au, 4.63% NiEq∆ SMSU waste: 0.300 mt at nil grade MSU waste: 0.169 mt at nil grade |

9 | Mill Treatment Capacity | 2,000 tonnes per day (tpd) |

10 | Mine life (excluding construction period) | 8 years (7.5 years excluding partial years) |

11 | Existing Project Infrastructure | Paved highway, grid power, railway line across site, port |

12 | Sustainable Development | There may be the potential for a solar garden on top of CFTF to generate clean energy post-mining |

*See Updated PEA for further details in respect of the above table

** Resources included in the Life of Mine Mill Feed were evaluated by calculating the NSR, using the following metal prices: $8.00/lb Ni, $3.00/lb Cu, $25/lb Co, $1,000/oz Pt, $1,000/oz Pd and $1,300/oz Au. Relevant functions were applied such as metal recovery curves, smelting and refining terms, transportation costs and state royalties. The calculated NSR was then compared to the operating cost per tonne to determine inclusion or exclusion of resource into the mine plan based on value addition or destruction. These costs are US$118/tonne for the SMSU and US$72/tonne for the MSU.

∆NiEq% = Ni%+ Cu% x $3.00/$8.00 + Co% x $25.00/$8.00 + Pt [g/t]/31.103 x $1,000/$8.00/22.04 + Pd [g/t]/31.103 x

$1,000/$8.00/22.04 + Au [g/t]/31.103 x $1,300/$8.00/22.04

Capital and Operating Costs

Capital costs for the Tamarack North Project were estimated by DRA Americas for the mine, process and surface facilities, and by SLR Consulting Limited for the CFTF. All cost estimates have been forecast in US dollars using constant, first quarter 2020 dollars, (i.e. in “real” dollars), without provision for inflation or escalation, and are subject to change if new information is received or circumstances change.

The total estimated capital cost is US$258.73M (which includes an estimated US$10.0M mill salvage credit and $10.32M of closure costs), of which US$218.60M is the initial cost required during the first 2.5 years prior to the start of production. The amounts include indirect costs and amounts for contingency. Contingency varies by line item, averages 20% for the initial cost of the mine and 23.4% for the initial cost of the process and surface facilities, and totals US$37.08M of the total initial cost of $218.60M.

Capital costs are detailed in the following table.

Table 3: Capital costs

U.S. dollars millions | Initial capital cost | Sustaining capital cost | Total |

Mine | 83.33 | 49.28 | 132.61 |

Process and Surface Facilities | 122.32 | 3.48 | 125.80 |

Sale of moveable equipment and mill at end of mine life | – | (10.00) | (10.00) |

Closure costs | – | 10.32 | 10.32 |

Working capital | 12.95 | (12.95) | – |

Total* | 218.60 | 40.13 | 258.73 |

*Totals may not add due to rounding

The average operating costs per tonne milled for the eight year mine life is US$87.73 per tonne milled and is detailed in the table that follows.

Table 4: Operating cost per tonne

Mining | US$/tonne | $50.34 |

Processing | US$/tonne | $14.69 |

Product handling, transportation, losses and insurance |

US$/tonne | $13.52 |

CFTF | US$/tonne | $1.67 |

General and administrative | US$/tonne | $7.50 |

Total | US$/tonne | $87.73 |

*Totals may not add due to rounding

C1 cost is US$2.67 per lb of nickel in concentrate and includes on-site costs, value of metal claimed by smelter (metal units, treatment charges and refining charges), insurance, losses and transportation costs, less the value of by-products such as copper and cobalt. C1 cost is not an IFRS (International Financial Reporting Standards) measure and, although it is calculated according to accepted industry practice, the C1 cost may not be directly comparable to calculations carried out by other companies.

Capital intensity is $21,000 per annual tonne of payable nickel equivalent and $15,000 per annual tonne of nickel produced in concentrate (excluding the impact of ramp-up/partial years in the first and last two years of the mine plan).

Economic Analysis

At base case metal prices, the Tamarack North Project has an after-tax NPV of US$291M using a discount rate of 7% and an after-tax IRR of 36%. Payback from start of construction is 2.3 years on a pre-tax basis and 2.5 years after-tax. All amounts are in U.S. dollars.

The Updated PEA illustrates a high after-tax IRR, low C1 cost, low capital intensity and a quick payback.

Metal prices used for the base case as well as for sensitivity cases are summarized in the table that follows. Base case prices were based on analyst consensus long-term prices. “Low” was used to estimate a pessimistic scenario. Incentive pricing is based on the price required to incentivize new mines to meet the projected increased demand for battery metals such as nickel and cobalt during the next decade.

Table 5: Assumed Metal Prices

| Unit | Low | Base case | Incentive pricing |

Ni | US$/lb | $6.75 | $8.00 | $9.50 |

Cu | US$/lb | $2.75 | $3.00 | $3.25 |

Co | US$/lb | $15.00 | $25.00 | $35.00 |

Pt | US$/oz | $1,000 | $1,000 | $1,000 |

Pd | US$/oz | $1,000 | $1,000 | $1,000 |

Au | US$/oz | $1,300 | $1,300 | $1,300 |

After-tax and pre-tax NPV and IRR, C1 cost per pound of nickel in concentrate and payback period from start of production in years for each pricing scenario is summarized in the table that follows.

Table 6: After-tax and Pre-tax NPV in US$ Millions, After-tax and Pre-tax IRR, C1 Cost and Payback Period Using Low, Base Case and Incentive Metal Price Assumptions

| After-tax | Pre-tax | |||||

Metal price scenario | Metal price scenario | ||||||

Low | Base | Incentive | Low | Base | Incentive | ||

Discount rate | NPV 7% | 191 | 291 | 398 | 242 | 362 | 492 |

NPV 8% | 174 | 268 | 370 | 222 | 335 | 458 | |

NPV 10% | 142 | 227 | 318 | 185 | 287 | 397 | |

IRR | 27.3% | 36.0% | 44.6% | 31.4% | 41.0% | 50.5% | |

C1 Cost per lb of Ni in concentrate |

$2.56 |

$2.67 |

$2.85 |

$2.56 |

$2.67 |

$2.85 | |

Payback in years from start of production |

2.9 |

2.5 |

2.1 |

2.7 |

2.3 |

2.0 | |

The following table sets out a summary of the Updated PEA:

Table 7: Summary of Updated PEA

Parameter | Result |

Tonnes processed (Mt) | 4.91 |

NiEq4 grade of tonnes processed | 2.82% |

NiEq4 lbs millions of tonnes processed | 305 |

Nickel recovery to nickel concentrate | 83.4% |

Copper recovery to Cu Concentrate | 80.2% |

Total copper recovery | 94.4% |

Net Ni concentrate payability (NSR / Value in concentrate) | 67.9% |

Ni concentrate grade | 13.3% |

Cu concentrate grade | 27.6% |

Revenue percentage split (Ni/Cu/Co/Pt+Pd+Au) | 77/19/3/1 |

Operating costs per tonne: Mining cost per tonne |

$50.34 |

Processing cost per tonne | $14.69 |

Product handling, transportation, losses and insurance per tonne | $13.52 |

Co-disposed Filtered Tailings Facility | $1.67 |

General & administrative | $7.50 |

Total operating cost per tonne | $87.73 |

C1 cost per lb of nickel in concentrate | $2.67 |

C1 cost plus royalties per lb of nickel in concentrate | $3.35 |

All-in sustaining cost per lb of nickel in concentrate (excludes initial CAPEX) |

$3.57 |

C1 cost plus royalties and total CAPEX per lb of nickel in concentrate | $4.72 |

Mill treatment capacity (tpd) | 2,000 |

Initial CAPEX (including working capital) (USD millions) | 219 |

Total CAPEX (USD millions) | 259 |

Mine life in years (excluding partial years) | 8 (7.5) |

Triple Flag Royalty | 1.85% |

Ni price per lb | $8.00 |

Cu price per lb | $3.00 |

Co price per lb | $25.00 |

NPV (USD millions) | 291 |

NPV per lb of NiEq4 | $0.95 |

After-tax IRR | 36.0% |

Payback period from start of production – pre-tax in years | 2.3 |

Payback period from start of production – after-tax in years | 2.5 |

4 NiEq% = Ni%+ Cu% x $3.00/$8.00 + Co% x $25.00/$8.00 + Pt [g/t]/31.103 x $1,000/$8.00/22.04 + Pd [g/t]/31.103 x

$1,000/$8.00/22.04 + Au [g/t]/31.103 x $1,300/$8.00/22.04

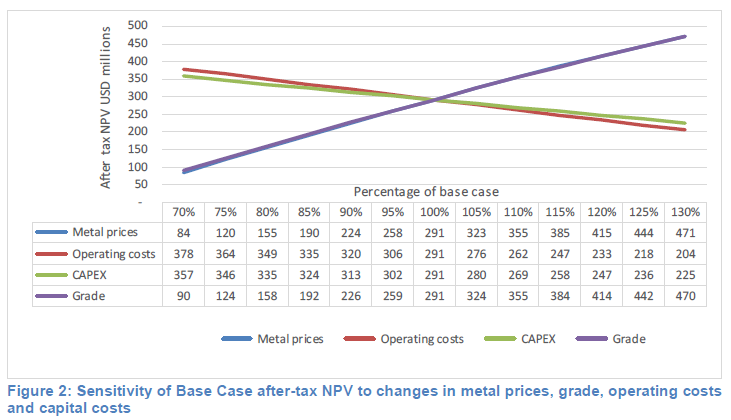

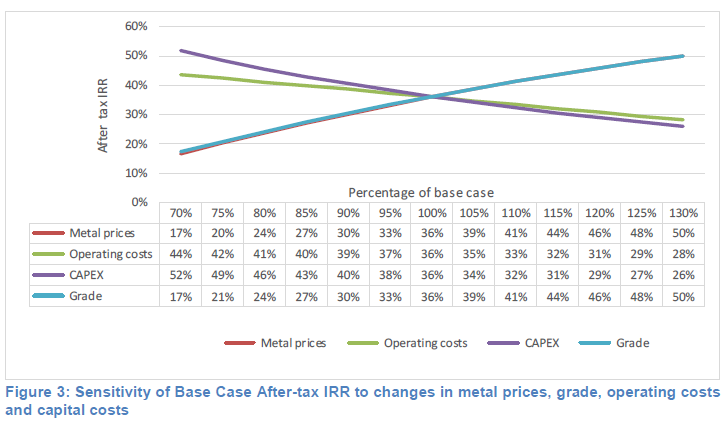

After-tax NPV and After-tax IRR Sensitivity

The sensitivity of the base case after-tax NPV and after-tax IRR was tested assuming changes in metal prices, operating costs, grade and capital costs in a range of +/-30% around the base case as shown in the following two figures.

| 70% | 75% | 80% | 85% | 90% | 95% | 100% | 105% | 110% | 115% | 120% | 125% | 130% |

Metal prices | 17% | 20% | 24% | 27% | 30% | 33% | 36% | 39% | 41% | 44% | 46% | 48% | 50% |

Operating costs | 44% | 42% | 41% | 40% | 39% | 37% | 36% | 35% | 33% | 32% | 31% | 29% | 28% |

CAPEX | 52% | 49% | 46% | 43% | 40% | 38% | 36% | 34% | 32% | 31% | 29% | 27% | 26% |

Grade | 17% | 21% | 24% | 27% | 30% | 33% | 36% | 39% | 41% | 44% | 46% | 48% | 50% |

Figure 3: Sensitivity of Base Case After-tax IRR to changes in metal prices, grade, operating costs and capital costs

Conclusions and Recommendations

The present mine plan is based on a subset of the mineral resource estimate within the Tamarack Zone as outlined in Table 2, which comprises a majority of the MSU, the lower SMSU and only a portion of the upper SMSU as further illustrated in Figure 1 above. The Updated PEA results are strong, with low case and base case after-tax IRR’s of 27% and 36%.

Under the Initial PEA, it was previously recommended that the Company take steps to complete a Pre-Feasibility Study (“PFS”) in respect of the Tamarack North Project. However, given the expected increase in demand for nickel in nickel sulphates in the coming years (which is used in the electric vehicle battery supply chain), coupled with the fact that the Tamarack Project is one of a few high-grade nickel sulphide projects on infrastructure that could potentially help fill in the predicted nickel sulphate supply gap, it is now recommended that Talon conducts several studies to determine the technical and financial viability of producing nickel sulphates at or from Tamarack. The outcome of these studies could materially change the Design Basis of a PFS. The nature of the specific studies to be conducted by the Company are summarized in the Updated PEA.

The technical report referenced herein (the Updated PEA) will be filed on SEDAR (www.sedar.com) and on the Company’s website (www.talonmetals.com) within 45 days.

Quality Assurance, Quality Control and Qualified Persons

For the purposes of the Updated PEA and this press release, the Qualified Persons (“QP”), as such term is defined in NI 43-101 are as follows:

The mineral resource estimate contained in this news release was prepared by or under the supervision of Mr. Brian Thomas (P.Geo.), who is a geologist independent of Talon and an employee of Golder Associates Ltd. In addition, Mr. Thomas has reviewed the sampling, analytical and test data underlying such information and has visited the site and reviewed and verified the QA/QC procedures used by Kennecott Exploration Company at the Tamarack North Project and found them to be consistent with industry standards. In Golder’s opinion, the mineral resource estimate disclosed herein has been prepared in accordance with CIM best practice guidelines. For further detail please see the Technical Report entitled “Second Independent Technical Report on the Tamarack North Project – Tamarack, Minnesota”, dated March 26, 2018, authored by DRA, which is available under the Company’s issuer profile on SEDAR (www.sedar.com).

The overall Updated PEA was compiled (with inputs from other QPs as indicated) by Mr. Tim Fletcher, P. Eng., a Senior Project Manager with DRA Americas who is independent of the Company.

The mining method, including mine development and mine plan, were developed by Mr. Andre- Francois Gravel, P. Eng., Sr. Mining Engineer for DRA Americas who is independent of the Company.

The mine capex and opex were developed by Mr. Daniel M. Gagnon, P. Eng., Sr. Mining Engineer and VP Mining and Geology for DRA Americas who is independent of the Company and has visited the site.

A summary of metallurgical test work and proposed ore processing methods for the project were compiled by Mr. Oliver Peters, P. Eng., Principal Metallurgist and President of Metpro who is independent of the company.

The economic analysis, including pre-tax and after-tax financial results and sensitivity analysis was completed Mr. Christian Hizmeri, MBA, Financial Analyst for DRA Americas (under the supervision of Mr. Daniel M. Gagnon, P. Eng.) who are independent of the Company.

The conceptual design of the CFTF was completed by Mr. David Ritchie, P.Eng., Mine Waste Engineering Manager with SLR Consulting (Canada) Ltd. who is independent of the Company.

The requirements for the backfill paste recipe and underground distribution methodology were reviewed by Mr. Leslie Correia, Pr. Eng., Engineering Manager for Paterson & Cooke Canada Inc.

Environmental considerations and permitting were addressed by Ms. Tina Pint, PG, a Senior Hydrogeologist and Vice President with Barr Engineering Co. in Minnesota. Ms. Pint has visited the site, and has reviewed and verified detailed environmental study requirements used by Talon for the Tamarack North Project and found them to be consistent with industry standards.

About Talon

Talon is a TSX-listed base metals company in a joint venture with Rio Tinto on the high-grade Tamarack Nickel-Copper-Cobalt Project located in Minnesota, USA, comprised of the Tamarack North Project and the Tamarack South Project. Talon has an earn-in right to acquire up to 60% of the Tamarack Project. The Tamarack Project comprises a large land position (18km of strike length) with numerous high-grade intercepts outside the current resource area. Talon is focused on expanding its current high-grade nickel mineralization resource prepared in accordance with NI 43-101; identifying additional high-grade nickel mineralization; and developing a process to potentially produce nickel sulphates responsibly for batteries for the electric vehicles industry. Talon has a well-qualified exploration and mine management team with extensive experience in project management.

For additional information on Talon, please visit the Company’s website at www.talonmetals.com or contact:

Sean Werger

President

Talon Metals Corp.

Tel: (416) 361-9636 x102

Email: werger@talonmetals.com

Forward-Looking Statements

This news release contains certain “forward-looking statements”. All statements, other than statements of historical fact that address activities, events or developments that the Company believes, expects or anticipates will or may occur in the future are forward-looking statements. These forward-looking statements reflect the current expectations or beliefs of the Company based on information currently available to the Company. Such forward-looking statements include, among other things, statements relating to the results of the Updated PEA with respect to estimates of mineral resource quantities, the mining method, the basis of design of the Updated PEA, capital and operating costs, NPV, IRR, payback, cash costs, targets, goals, objectives and plans, including conducting several studies to determine the technical and financial viability of producing nickel sulphates at Tamarack the outcome of which could materially change the Design Basis of a PFS, exploration results and near-by exploration, opportunities to further increase the tonnage in the mine plan, the mine life and production rate, as well as to decrease mining OPEX and CAPEX, further optimize the metallurgical recoveries, and assumptions in respect of metal pricing.

Forward-looking statements are subject to significant risks and uncertainties and other factors that could cause the actual results to differ materially from those discussed in the forward-looking statements, and even if such actual results are realized or substantially realized, there can be no assurance that they will have the expected consequences to, or effects on the Company. Factors that could cause actual results or events to differ materially from current expectations include, but are not limited to: failure to establish estimated mineral resources, the grade, quality and recovery of mineral resources varying from estimates, the uncertainties involved in interpreting drilling results and other geological data, inaccurate geological and metallurgical assumptions, including with respect to the size, grade and recoverability of mineral reserves and resources, uncertainties relating to the financing needed to further explore and develop the properties or to put a mine into production and other factors including exploration, development and operating risks, uncertainties with economic estimates, capital and operating costs, mine plan and development issues.

Any forward-looking statement speaks only as of the date on which it is made and, except as may be required by applicable securities laws, the Company disclaims any intent or obligation to update any forward-looking statement, whether as a result of new information, future events or results or otherwise. Although the Company believes that the assumptions inherent in the forward- looking statements are reasonable, forward-looking statements are not guarantees of future performance and accordingly undue reliance should not be put on such statements due to the inherent uncertainty therein.

The mineral resource figures disclosed in this news release are estimates and no assurances can be given that the indicated levels of nickel, copper, cobalt, platinum, palladium and gold will be produced. Such estimates are expressions of judgment based on knowledge, mining experience, analysis of drilling results and industry practices. Valid estimates made at a given time may significantly change when new information becomes available. While the Company believes that the resource estimates disclosed in this news release are accurate, by their nature resource estimates are imprecise and depend, to a certain extent, upon statistical inferences which may ultimately prove unreliable. If such estimates are inaccurate or are reduced in the future, this could have a material adverse impact on the Company. Mineral resources are not mineral reserves and do not have demonstrated economic viability. Inferred mineral resources are estimated on limited information not sufficient to verify geological and grade continuity or to allow technical and economic parameters to be applied. Inferred mineral resources are too speculative geologically to have economic considerations applied to them to enable them to be categorized as mineral reserves. There is no certainty that mineral resources can be upgraded to mineral reserves through continued exploration.